Imagine a world where industry giants rely on precision and efficiency to thrive. Electrode making machines are at the heart of this revolution, producing essential components for various sectors. These machines are pivotal for industries like automotive, shipbuilding, and structural steel fabrication. In this post, you'll learn about the key industries utilizing these machines and the technological advancements driving their evolution.

Structural Steel Fabrication

Role of Electrode Making Machines in Steel Fabrication

Electrode making machines play a crucial role in structural steel fabrication by producing high-quality welding electrodes essential for joining steel components. These machines ensure electrodes have consistent size, coating, and chemical composition, which directly impact weld strength and durability. In steel fabrication, electrodes act as the conductor for the welding current and provide filler material that bonds steel parts together. Precision in electrode manufacturing minimizes defects like cracks or porosity in welds, which is vital for structures bearing heavy loads.

The machines handle processes such as wire drawing, coating application, drying, and baking to create electrodes tailored for specific steel grades and fabrication needs. Automation in these machines boosts production rates and maintains uniformity, which is critical for large-scale projects. By producing electrodes that meet industry standards, these machines support fabricators in delivering safe and reliable steel frameworks.

Benefits of Using High-Quality Electrodes

Using high-quality electrodes made by advanced electrode making machines offers several benefits:

| Improved Weld Strength | Consistent electrode quality ensures strong weld joints that withstand mechanical stresses. |

| Reduced Rework | High-quality electrodes reduce weld defects, lowering the need for costly repairs and saving time. |

| Enhanced Safety | Reliable welds contribute to the overall safety of steel structures, especially in critical infrastructure. |

| Better Arc Stability | Superior electrodes provide stable arcs, making welding easier and more efficient for operators. |

| Corrosion Resistance | Electrodes with specialized coatings enhance resistance to environmental degradation, extending structure lifespan. |

These benefits lead to cost savings and higher productivity for steel fabricators, especially when working on demanding projects.

Case Studies: Skyscraper Construction

In skyscraper construction, the demand for strong and precise welds is exceptionally high. Electrode making machines produce electrodes that meet stringent safety codes and engineering specifications. For example, in North America and Europe, skyscraper projects have reported up to a 15% reduction in weld rework by adopting electrodes from advanced manufacturing lines.

One notable case involved a high-rise project where electrode consistency allowed welders to complete steel beam joints faster while maintaining structural integrity. This efficiency translated to shorter construction timelines and improved budget adherence. The use of electrodes tailored to specific steel alloys also helped withstand dynamic loads like wind and seismic activity.

Such case studies highlight how electrode making machines contribute to the success of complex structural steel fabrication projects by ensuring weld quality and reliability.

Tip: Regularly verify that electrodes meet project-specific standards to avoid weld defects and costly rework in structural steel fabrication.

Shipbuilding and Marine Applications

Challenges in Marine-Grade Steel Welding

Welding in shipbuilding faces unique challenges due to the harsh marine environment. Steel used in ships must endure constant exposure to saltwater, waves, and fluctuating temperatures. These conditions can cause corrosion and fatigue, making weld quality critical for safety and longevity. Marine-grade steel often contains special alloys to improve strength and corrosion resistance, but welding it requires electrodes that match these properties exactly.

One major challenge is controlling hydrogen-induced cracking. Saltwater increases moisture, which can lead to hydrogen absorption during welding. If electrodes are not properly manufactured or stored, welds may develop cracks, risking structural failure. Furthermore, thick steel plates used in ship hulls require electrodes that can maintain arc stability and produce deep, defect-free welds.

Electrode Making Machines for Corrosion Resistance

Electrode making machines produce electrodes tailored for marine applications by applying specialized coatings that enhance corrosion resistance. These coatings often include compounds that form protective slag layers during welding, shielding the weld pool from oxygen and contaminants. Machines ensure precise coating thickness and uniformity, which are essential for consistent weld quality.

Advanced machines also control the chemical composition of the electrode core wire, matching marine steel alloys to maintain mechanical properties after welding. By automating processes like wire drawing, coating application, and baking, these machines reduce defects and improve electrode performance.

For example, Hyundai Heavy Industries uses electrodes manufactured with strict quality controls to meet international marine standards. These electrodes help build ships that last longer and require less maintenance.

Automation Trends in Shipyards

Shipyards worldwide are increasingly adopting automation to boost efficiency and quality. Electrode making machines now integrate with smart factory systems, allowing real-time monitoring and adaptive control. This reduces waste and improves production speed.

Robotic welding systems in shipyards use electrodes produced by these machines to perform precise, repeatable welds on large ship components. Automation minimizes human error and enhances safety by reducing manual welding in hazardous conditions.

Collaborative robots, or cobots, assist workers by handling electrode feeding and positioning, streamlining workflows. These trends not only improve shipbuilding productivity but also ensure that electrodes meet the demanding standards required for marine-grade steel welding.

Heavy Equipment Maintenance

Importance of Quick Repair Welds

Heavy equipment used in industries like mining, construction, and agriculture often faces harsh operating conditions. These machines are subject to constant wear, impacts, and heavy loads, which can cause parts to crack or break unexpectedly. Quick repair welds are crucial to minimize downtime and keep operations running smoothly. Electrode making machines produce electrodes designed for fast, reliable welding repairs that restore equipment function swiftly.

Speed matters because every hour of downtime can lead to significant productivity losses and increased operational costs. High-quality electrodes enable welders to perform repairs efficiently without compromising weld strength or durability. These electrodes often have coatings that promote stable arcs and reduce spatter, helping technicians complete repairs faster and with less cleanup.

Extending Equipment Lifespan with Electrode Making Machines

Using electrodes made by advanced electrode making machines contributes to extending heavy equipment lifespan. These machines ensure electrodes have consistent chemical composition and coating quality, which directly affect weld integrity. Properly made electrodes produce strong welds resistant to fatigue, cracking, and corrosion.

By restoring worn or damaged components with durable welds, companies can avoid costly replacements and extend the service life of expensive machinery. For example, mining operations report that using high-quality electrodes for repair welding can extend equipment life by up to 20%, reducing capital expenditure.

Electrode making machines can also customize electrodes for specific metals and operating environments, such as high-temperature or abrasive conditions. This customization ensures that repairs are tailored to the equipment’s needs, improving performance and reliability.

Cost Efficiency in Heavy Machinery Maintenance

Cost efficiency is a major driver behind the use of electrode making machines in heavy equipment maintenance. Producing electrodes in-house or sourcing from reliable manufacturers reduces dependency on external suppliers, lowering procurement costs. Consistent electrode quality also reduces repair failures and rework, saving labor and material expenses.

Moreover, quick repair welds reduce equipment downtime, which translates into higher operational uptime and better return on investment. The ability to perform maintenance on-site using tailored electrodes avoids costly equipment transport to repair shops.

Investing in modern electrode making machines with automation and quality control features further enhances cost efficiency. These machines minimize waste, optimize raw material use, and increase production speed, delivering electrodes at competitive prices without sacrificing quality.

Pipeline Welding

High Currents and Defect-Free Welds

Pipeline welding demands electrodes that perform flawlessly under high electrical currents. These currents generate the intense heat necessary to fuse thick pipeline steels, often buried underground or exposed to harsh conditions. Electrode making machines produce rods with precise core wire compositions and uniform coatings, ensuring the electrodes can handle high amperages without degrading or causing weld defects.

Defect-free welds are critical in pipelines to prevent leaks and failures. Machines ensure consistent electrode diameter and coating thickness, which stabilize the welding arc and promote smooth metal transfer. This consistency reduces common welding issues such as porosity, slag inclusions, or cracking, which could compromise pipeline integrity.

Environmental Safety and Compliance

Environmental safety is a top priority in pipeline construction and maintenance. Electrode making machines contribute by producing electrodes designed to meet strict environmental regulations. These electrodes minimize harmful emissions during welding and help create strong, corrosion-resistant welds that prevent leaks of hazardous materials.

Compliance with standards like API (American Petroleum Institute) and ISO ensures pipelines maintain safety and environmental protection throughout their lifespan. Machines can customize electrodes with coatings that resist soil corrosion and chemical attack, extending pipeline durability and reducing environmental risks.

Electrode Making Machines in Major Pipeline Projects

Major pipeline projects rely heavily on high-quality electrodes manufactured by advanced electrode making machines. For example, large-scale oil and gas pipelines in North America and Asia use electrodes produced under stringent quality controls to guarantee weld reliability across thousands of miles.

These machines integrate automation and real-time quality monitoring to produce electrodes rapidly while maintaining exact specifications. This capability supports tight project timelines and helps avoid costly weld failures or repairs. The ability to tailor electrodes for specific pipeline steels and welding conditions also enhances project success.

Automotive Manufacturing

Electrode Making Machines in Vehicle Assembly

In automotive manufacturing, electrode making machines play a vital role in producing welding electrodes used for assembling vehicle frames and components. These electrodes must meet strict quality standards to ensure strong, durable welds that keep vehicles safe and reliable. The machines produce electrodes with precise dimensions and consistent coatings, essential for maintaining weld integrity during high-speed assembly line processes.

Automakers rely on these machines to supply electrodes compatible with various welding methods, including MIG and resistance welding. This versatility supports the joining of different metals and alloys used in vehicle construction. Consistent electrode quality reduces weld defects, minimizes downtime, and enhances overall production efficiency.

Lightweight and Strong Welds for Electric Vehicles

The rise of electric vehicles (EVs) demands electrodes that can create lightweight yet strong welds. EV manufacturers require materials that reduce vehicle weight to improve battery range without sacrificing safety or durability. Electrode making machines produce specialized electrodes with advanced coatings and core compositions designed for aluminum and high-strength steel alloys commonly used in EV bodies.

These electrodes enable welds that withstand mechanical stress and corrosion while maintaining electrical conductivity where needed. Innovations in electrode materials also support joining dissimilar metals, a common challenge in EV assembly. By producing electrodes tailored for these applications, machines contribute directly to the performance and sustainability goals of electric vehicle production.

Improving Production Efficiency and Safety Standards

Electrode making machines enhance production efficiency by automating electrode manufacturing, ensuring uniform quality at high volumes. Automation reduces human error and speeds up electrode supply to welding stations, aligning with just-in-time manufacturing principles common in automotive plants.

Moreover, these machines incorporate quality control systems that detect defects early, preventing substandard electrodes from reaching the assembly line. This focus on quality supports compliance with stringent automotive safety standards, such as ISO/TS 16949, which demand reliable welds for crashworthiness and durability.

Safety improvements extend to the welding process itself. High-quality electrodes provide stable arcs, reducing spatter and fumes, which helps maintain a safer working environment for welders. By supporting both efficiency and safety, electrode making machines are indispensable in modern automotive manufacturing.

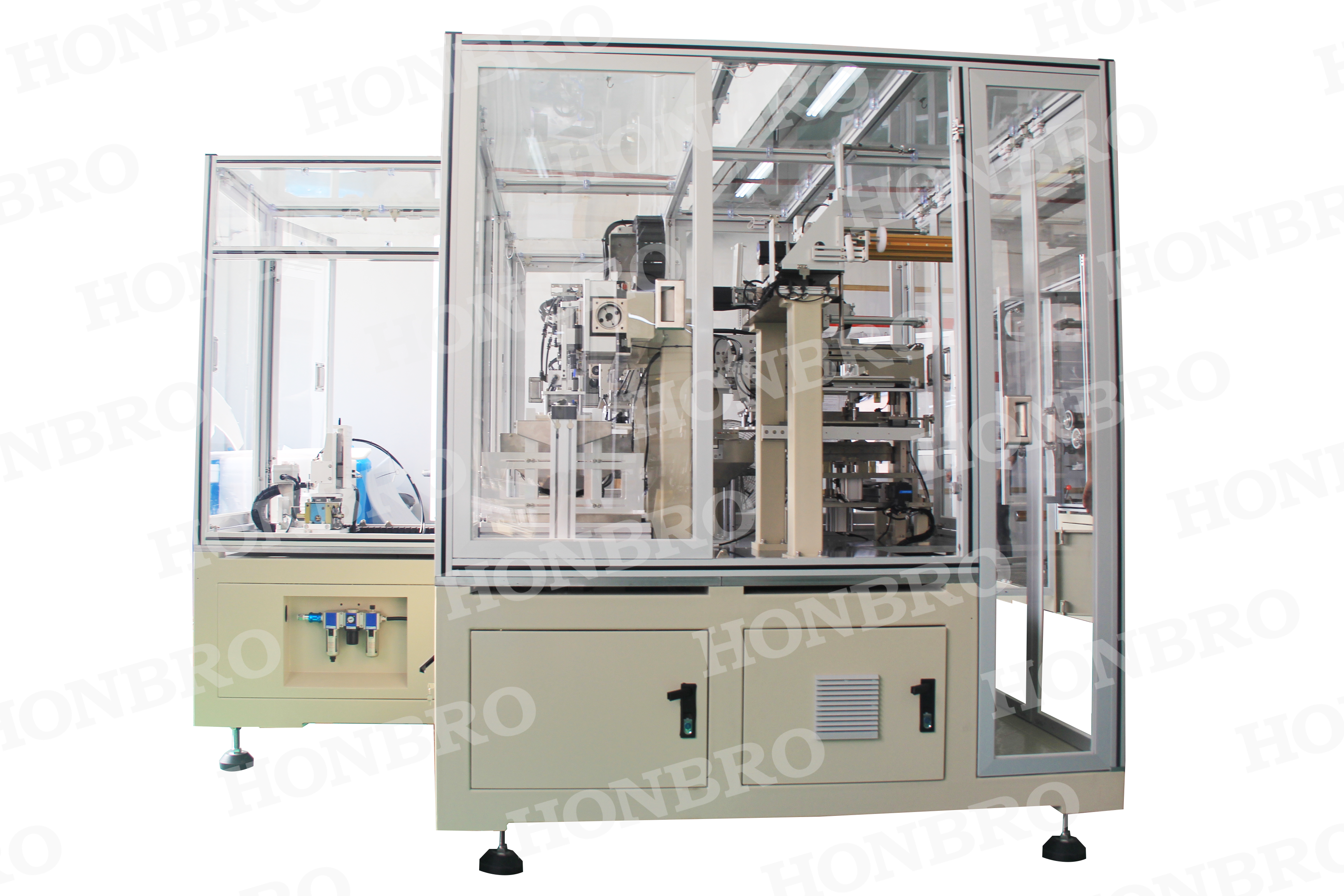

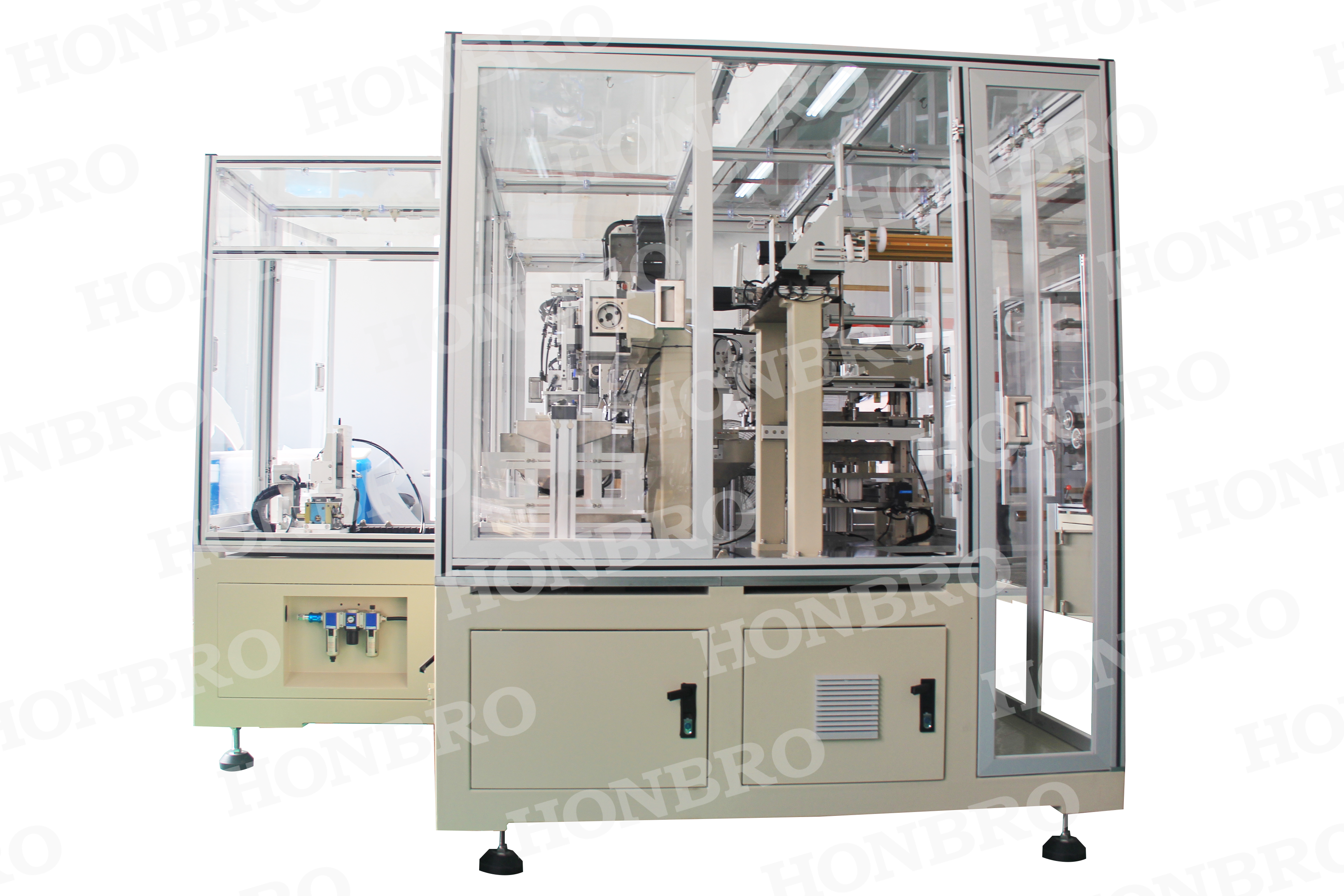

Key Innovations in Electrode Making Machines

Automation and Smart Factories

Modern electrode making machines have embraced automation, transforming traditional manufacturing into smart factories. These machines use robotics, AI, and the Internet of Things (IoT) to boost speed, accuracy, and consistency. Automation reduces manual labor while increasing output and lowering defects. For example, AI algorithms adjust machine parameters in real time to optimize electrode quality based on sensor feedback. IoT connectivity enables remote monitoring and predictive maintenance, minimizing downtime and maximizing productivity. This seamless integration supports large-scale production demands across industries such as automotive and pipeline construction.

Collaborative Robots (Cobots) in Electrode Production

Collaborative robots, or cobots, are revolutionizing electrode manufacturing by working safely alongside human operators. Unlike traditional robots, cobots are flexible and easily reprogrammable, ideal for small to medium batch sizes or frequent product changes. They handle tasks like electrode feeding, coating application, and packaging, improving workflow efficiency. Cobots also reduce ergonomic risks by taking over repetitive or strenuous jobs. This human-robot collaboration enhances production flexibility and quality control, enabling manufacturers to meet diverse industry requirements quickly without extensive downtime for retooling.

Precision Coating and Advanced Electrode Materials

Electrode performance heavily depends on coating quality and core material composition. Cutting-edge machines now feature precision coating systems that apply uniform layers at high speeds. These coatings can be customized in thickness, composition, and additives to improve arc stability, corrosion resistance, and weld strength. Advanced extrusion technology ensures flaw-free core wires, maintaining exact chemical compositions required for specialized applications. For instance, electrodes designed for marine or pipeline use often need coatings that resist harsh environments. These innovations enable manufacturers to produce electrodes tailored for demanding conditions, enhancing weld reliability and durability.

Conclusion

Electrode making machines play a vital role in industries like steel fabrication, shipbuilding, heavy equipment maintenance, pipeline welding, and automotive manufacturing. These machines ensure high-quality electrodes that enhance weld strength, reduce defects, and improve safety. The future of electrode making machines lies in automation and smart factories, which boost efficiency and quality. HONBRO's advanced machines provide exceptional value by integrating cutting-edge technology to meet diverse industry needs, ensuring reliable and efficient electrode production.

FAQ

Q: What is an Electrode Making Machine?

A: An Electrode Making Machine is a specialized device used to manufacture welding electrodes with consistent size, coating, and chemical composition, ensuring high-quality welds in various industries.

Q: How do Electrode Making Machines benefit structural steel fabrication?

A: Electrode Making Machines produce high-quality electrodes that improve weld strength, reduce rework, enhance safety, and provide better arc stability, crucial for reliable steel structures.

Q: Why are Electrode Making Machines important in shipbuilding?

A: They produce electrodes with specialized coatings that enhance corrosion resistance, essential for marine-grade steel welding, ensuring ship durability and compliance with safety standards.

Q: How do Electrode Making Machines improve heavy equipment maintenance?

A: They produce electrodes for quick repair welds, extending equipment lifespan and reducing downtime, which is vital for cost efficiency in heavy machinery maintenance.

Q: What role do Electrode Making Machines play in automotive manufacturing?

A: They produce electrodes for strong, durable welds in vehicle assembly, supporting production efficiency and compliance with safety standards, especially for electric vehicles.