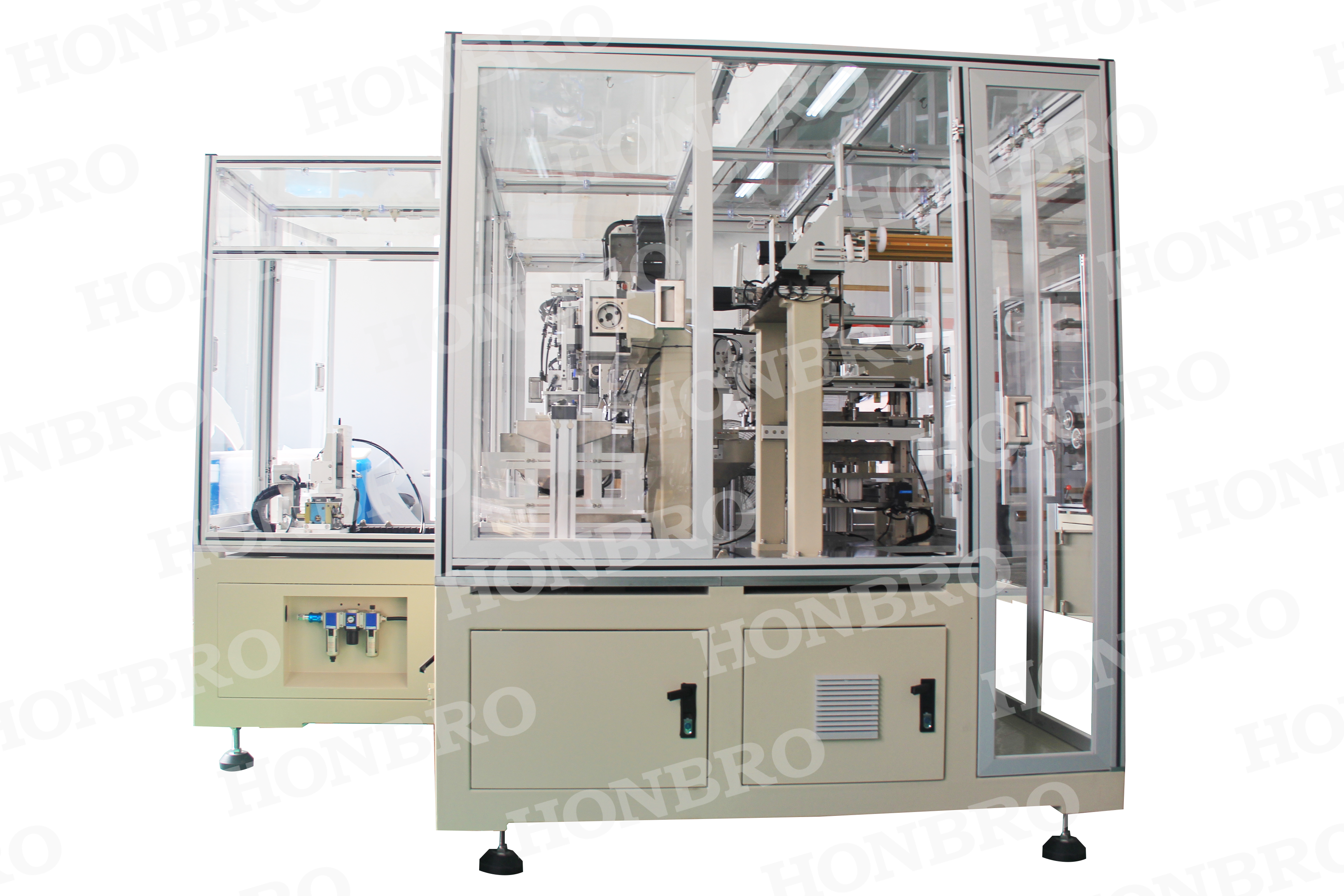

Product Overview:

Introducing the Auto Z-Stacking Machine (250 Type), a precision-engineered solution tailored for the meticulous fabrication of lithium-ion battery cells. This compact yet powerful machine specializes in executing the intricate Z-fold stacking of anode and cathode sheets alongside separators, ensuring optimal layering for superior battery output and longevity.

Core Functions & Attributes:

Precision Z-Lamination Process:

Expertly crafted to perform the Z-shape lamination of anodes, cathodes, and separators with unparalleled accuracy, vital for the battery's overall performance.

Versatile Anode Folding:

Offers flexible anode folding options, enabling either same-side or opposing-side ear folding to accommodate diverse battery designs and production specifications.

Integrated Heating & Glue Application:

Post-lamination, the separator undergoes precise heating followed by the application of side glue or flat glue, customizable to suit production preferences, ensuring a sturdy bond and battery structure.

Configurable for Optimal Efficiency:

Users can personalize settings such as the glue application method and manage end-coil separator operations, including adjusting the number of turns, to streamline the manufacturing process to their exact needs.

Seamless Integration & Scalability:

Designed for direct interface with existing conveyor systems, facilitating a continuous workflow without interruptions.

Future-ready with upgrade paths to convert into a combined cutting and folding machine, enhancing the unit's versatility and production capacity.

Enhanced Quality Control:

Incorporates a dust extraction system at the cell's terminus post-separator cutting, maintaining a contaminant-free environment and upholding premium product standards.

The Auto Z-Stacking Machine (250 Type) represents a strategic investment for manufacturers seeking to enhance the productivity and precision of their lithium-ion cell production lines. Its adaptable features, coupled with potential for expansion, make it a cornerstone equipment for meeting today's demanding battery production requirements and preparing for tomorrow's advancements.

Technical Parameters

| Item | 250 Type |

| Electrode location mode | Mechanical positioning |

| Single piece efficiency | 0.5-1S/PCS |

| Compatible electrode size | L150-250mm |

| L80-200mm |

| Stacking table structure | Cam press claw |

| Ultrasonic missing Angle detection | Standard |

| Alignment of adjacent electrode | ≤±0.2mm |

| Overall alignment of electrode | ≤±0.4mm |

| Alignment between the electrode and the adjacent separator | ≤±0.4mm |

| Separator cut-off and reverse closure time | ≤12S |

| Dusting mode | The top of the equipment is equipped with FFU to remove dust |

| Separator electrostatic removal | Standard |

| MES function | It can dock with MES system |